|

Entry No.79 |

|

|

MODEL CHARACTERISTICS: YAMAHA YZR-M1 2006 CAMEL TEAM. I AM BUILDING THIS VERSION OF M1 BIKE FROM THE 2005 TAMIYA KIT. AS YOU CAN SEE ON PICTURES THE COWLING IS HAND MODIFIED NOT A S27 UPGRADE. I AM DOING THE EARLY BIKE WHIT THE REAR COWL LIKE AN ARROW SHAPE, THATS BECAUSE I AM ALSO BUILDING DE 2007 BIKE JUST DONT HAVE SOME ENGINE PHOTOS TO MAKE THE COPY. I ALSO MADE MY OWN DECALS, AND BUILD IN MY LABORATORY SOME METAL PARTS. NOT WHITE METAL!!! I MADE CHROME NIQUEL PARTS LIKE BRAKE CALIPERS, REAR BRAKE TANK AND OTHER PARTS. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

this photo show the front cowling being preparated to reform the wind shield. |

|

covered with hard silicone to copy the shape. |

|

this is the silicone i use. |

|

this are the separated parts and the silicone pattern. |

|

here i made a mark to the silicone mold to know the limit of the 2006/2007 model. |

|

the blue material is dental acrylic. |

|

the parts of the mold, ready to be finished. |

|

now the mold to make the vacumm formed wing shields. |

|

the mold ready. |

|

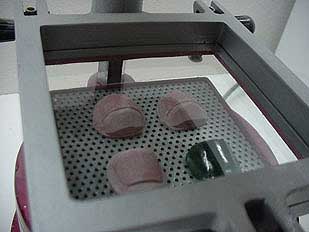

the molds to be vacum forme in the vacum machine. |

|

parts ready to be cutted. |

|

the rear brake piston fixed on the frame must be modified. The reservoir tank for brake fluid must be included into the piston. |

|

here is the original part from tamiya kit that represents the reservoir tank. |

|

the tank is separated. |

|

now i copy with the same silicone before used. |

|

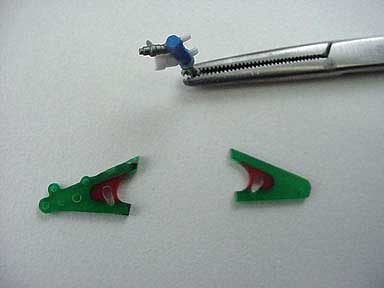

here is the modified parts. Copied, and maked in acrilic, styrene, and same parts from tamiya kit to get the parte needed. |

|

close view of the right part. |

|

to get a stronger piece to be copied and reproduced, I cast this plastic parts into Chrome Niquel alloy. In this photo you can see the silicone base and the parts atached, ready to be filled whit a refractary material. |

|

here the refractary material fills the mold whit the parts inside, and after it become hard and burn into an electric oven at 900¼C, the acrylic, styerne, wax and all burnable materials completely calcinate. And only have to fill the empty spasy whit the metal at 1300¼C. |

|

After remove the burned refractary material and sanded with aluminium oxyde this is the result. |

|

here the metal parts. Now, rest to cut, correct and polish to get the final parts to be copied or used. |

|

|

|

|

|

|